A self-locking lead screw offers several advantages, especially in applications where precise control and stability are critical. Here's how this feature impacts the design of machinery:

Advantages of Self-Locking Lead Screws:

Prevents Backdriving: A self-locking lead screw resists reverse rotation under load, preventing the nut from moving when the driving force is removed. This is particularly valuable in systems where gravity or external forces could cause unwanted movement, such as in vertical applications or lifting mechanisms.

Energy Efficiency: Since the nut cannot easily move in the opposite direction under load, self-locking lead screws save energy that would otherwise be needed to counteract the backdriving forces. This feature can make machinery more energy-efficient, especially in applications like screw jacks or actuators.

Safety and Stability: The self-locking property ensures that the load remains in place even if the drive motor is turned off or if power failure occurs. This feature enhances safety in systems like adjustable-height tables, medical equipment, or any machinery where an unexpected movement could cause damage or harm.

Simplifies Design: The ability to lock the position of the nut means that additional locking mechanisms, brakes, or clutches are often unnecessary. This can simplify the overall design and reduce the complexity of the system, saving both cost and space.

Reduced Need for External Holding Mechanisms: In some systems, especially in heavy-duty or high-load applications, a self-locking lead screw can eliminate the need for external holding mechanisms such as clamps or brakes. This makes the design less cluttered and more reliable over time.

Impact on Machinery Design:

Load Handling: Self-locking lead screws are often used in applications where high load stability is required. The design of machinery needs to account for the lead angle and thread geometry that enable self-locking—typically a steep lead angle combined with a high frictional resistance. This could affect the overall mechanical efficiency, as higher friction may result in greater energy losses.

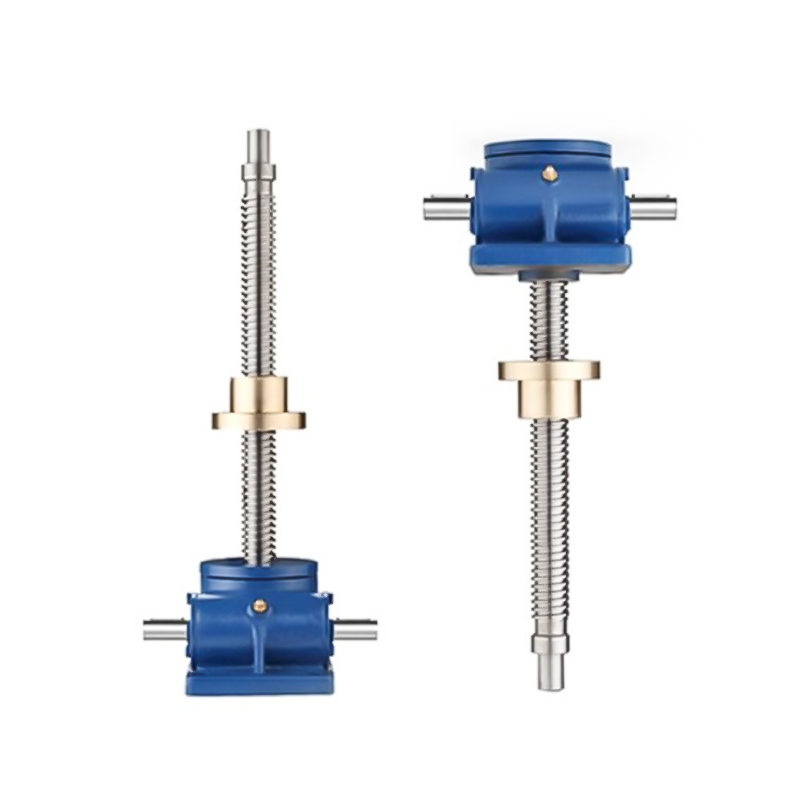

Choice of Materials: The material choice for the lead screw and nut becomes more important in self-locking designs, as higher friction is needed for the locking action. Materials with high friction coefficients, such as bronze or certain composites, are often selected to achieve self-locking properties.

Speed vs. Torque Trade-Off: Self-locking lead screws typically operate at lower speeds compared to non-locking variants. Designers must balance the need for self-locking with the application's speed and efficiency requirements. This might limit the use of self-locking lead screws in applications requiring high-speed movement.

Thermal Management: The increased friction associated with self-locking lead screws may lead to more heat generation. Designers need to incorporate adequate cooling or lubrication solutions to manage heat buildup, which could affect the longevity and performance of the system.

Precise Positioning: The self-locking feature helps maintain precise positioning without the need for continuous power to the driving motor. This is beneficial in applications requiring accurate, stable positions, such as in positioning systems or actuators in robotics, CNC machines, and adjustable mechanisms.

English

English 中文简体

中文简体 Español

Español русский

русский عربى

عربى